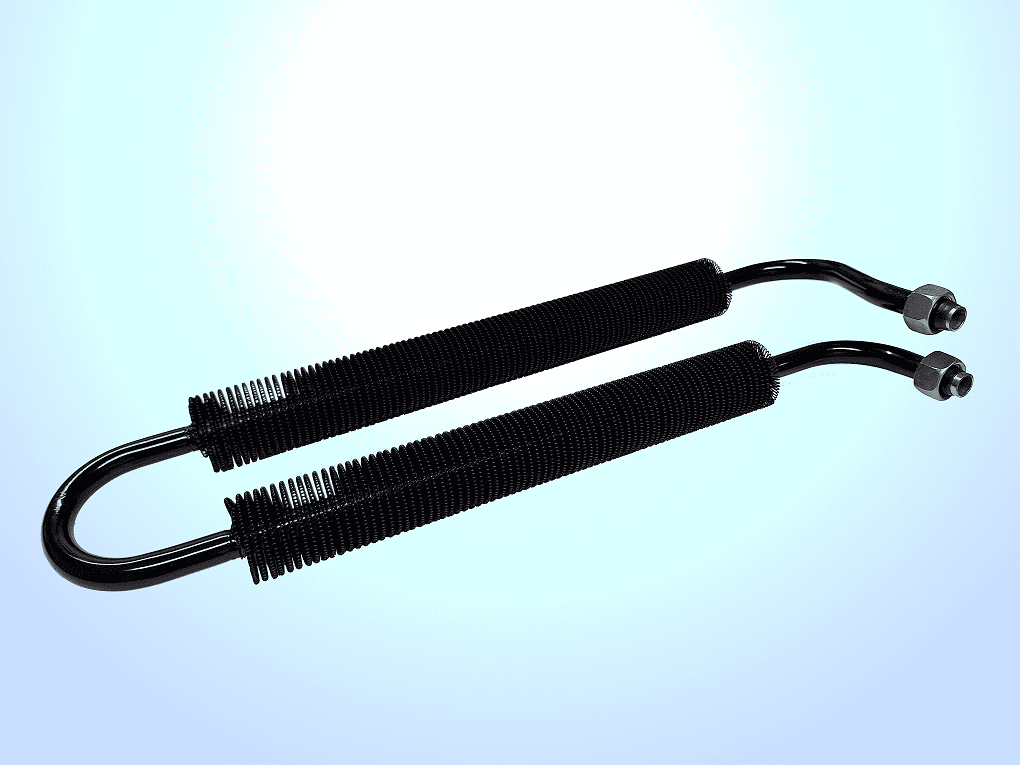

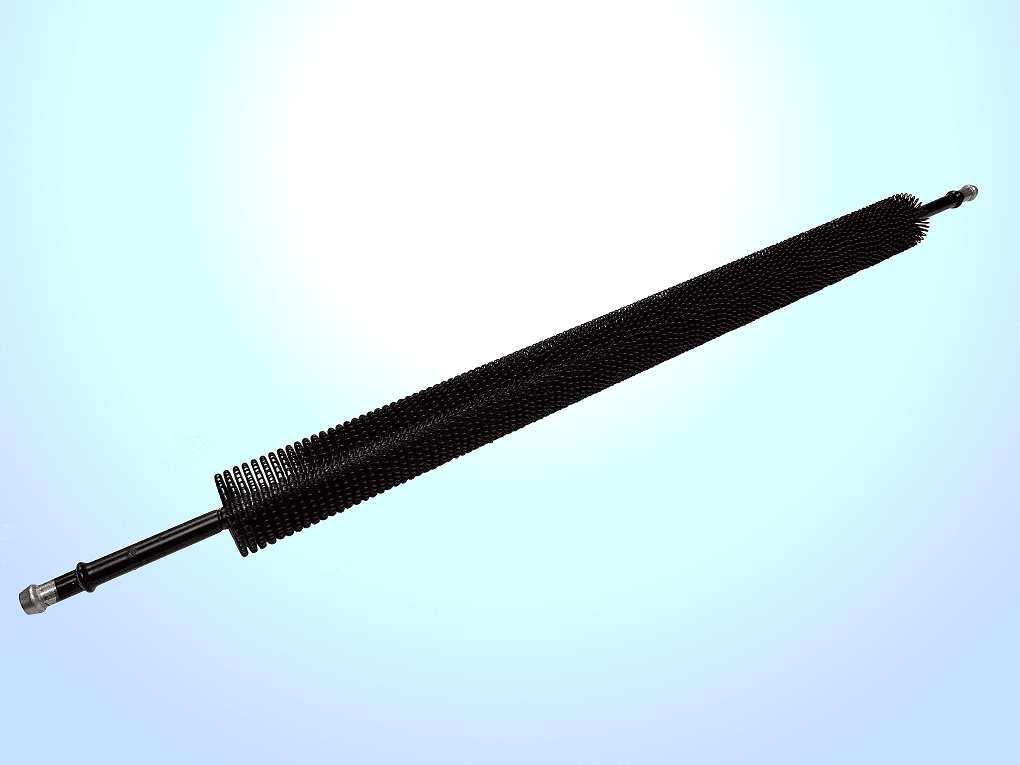

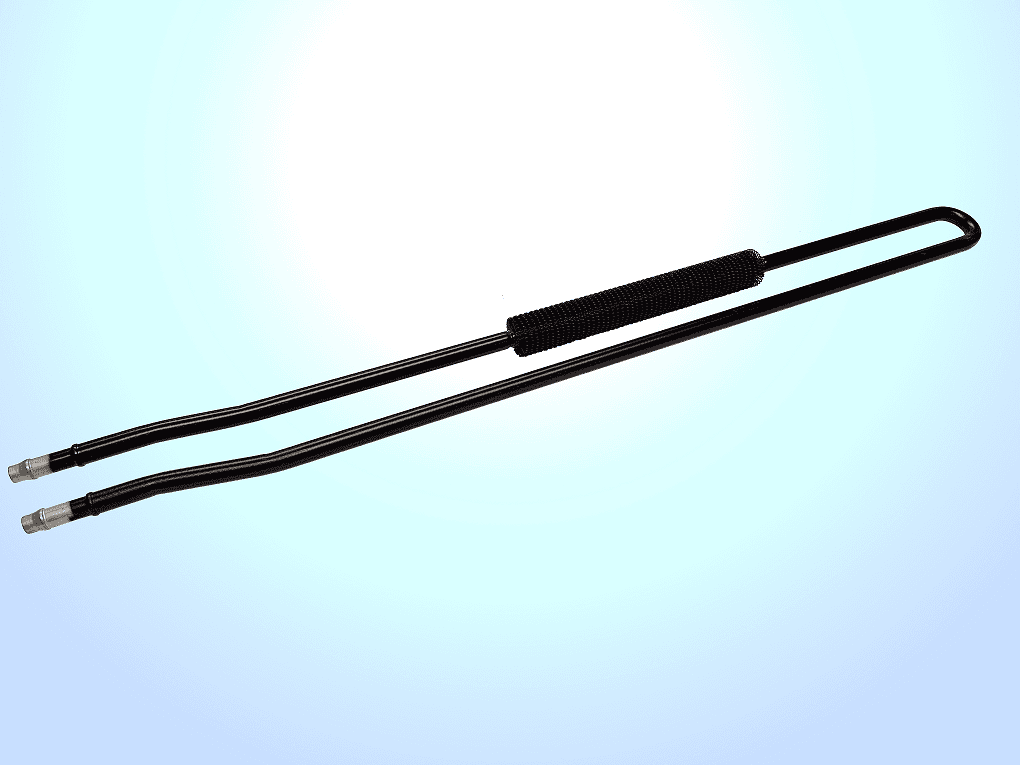

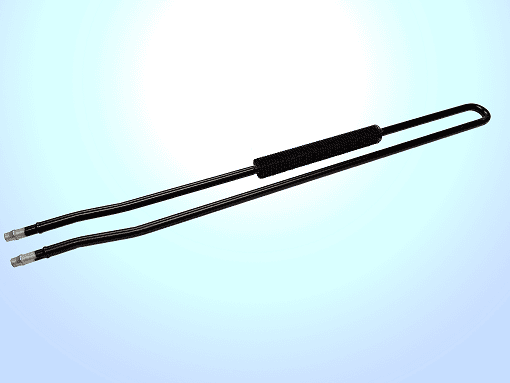

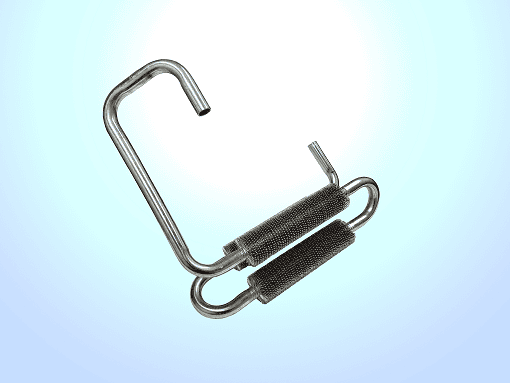

The automotive market for heat exchangers requires a different set of requirements than other industries. Cost, mass and packing constraints are key drivers for this product, as they affect the fuel efficiency, performance, and emissions of the vehicle. Aluminium wire fin on tube is ideally suited to meet all the 3 key constraints, as it offers a high heat transfer coefficient, a low weight, and a compact design. Fins can be added to long lengths of tube without joints , so that the heat exchanger becomes part of the fluid line, reducing the number of fittings and potential leak points.

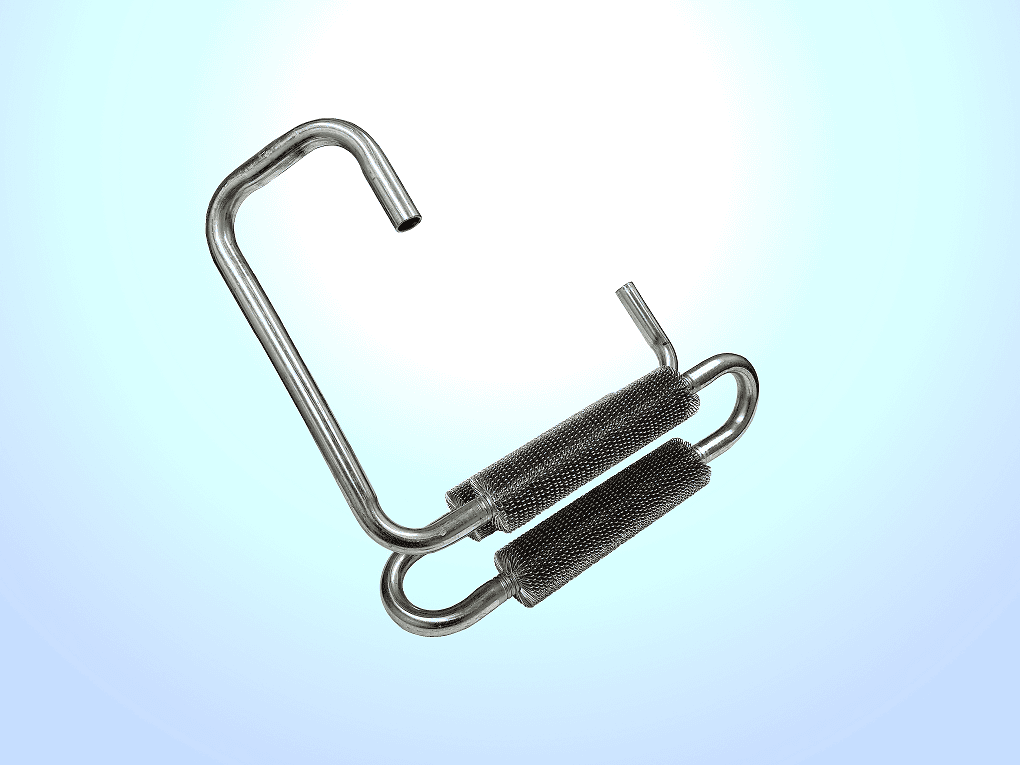

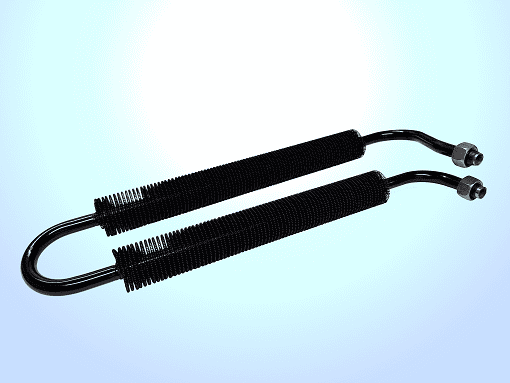

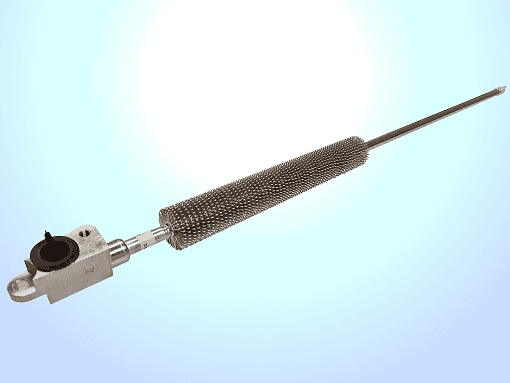

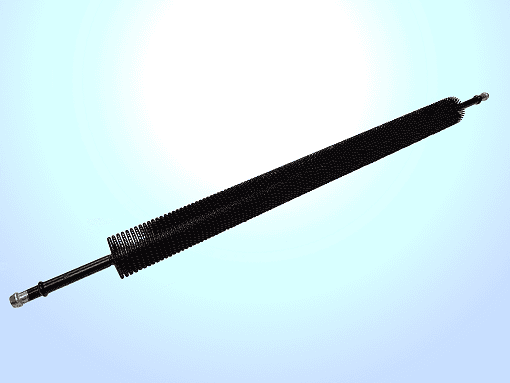

Automotive Tubes

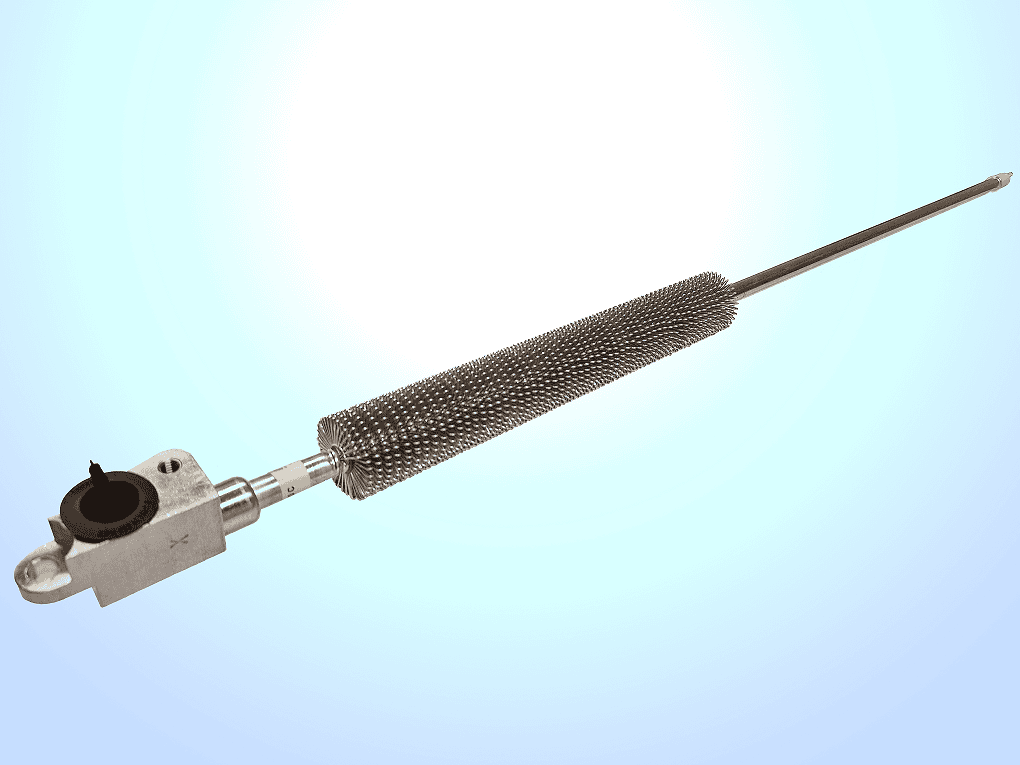

The wire fin technology operates well in confused air flow application as the thermal performance is not hindered in this environment. The wire fins create turbulence in the air flow, enhancing the heat transfer and reducing the air-side pressure drop. These heat exchangers can also be used for high pressure applications, as the application of the fin does not affect the mechanical integrity of the tubing.

Aluminium is the most common fin and tubing material, as it has a high thermal conductivity, a good corrosion resistance, and a low cost. However, stainless steel and plated carbon steel tubing can also be used where the application requires extra strength or durability, such as in harsh environments or high-temperature applications. A range of tube diameters and fin configurations are available to meet customer requirements. We can also customise the shape, size, and layout of the heat exchanger, to fit the available space and optimise the performance.