These coolers are very common in industry and generally do not require internal extended surface to benefit the heat transfer due to water wanting to give the heat up relatively easily. Some additional surface may be required for strong glycol mixtures.

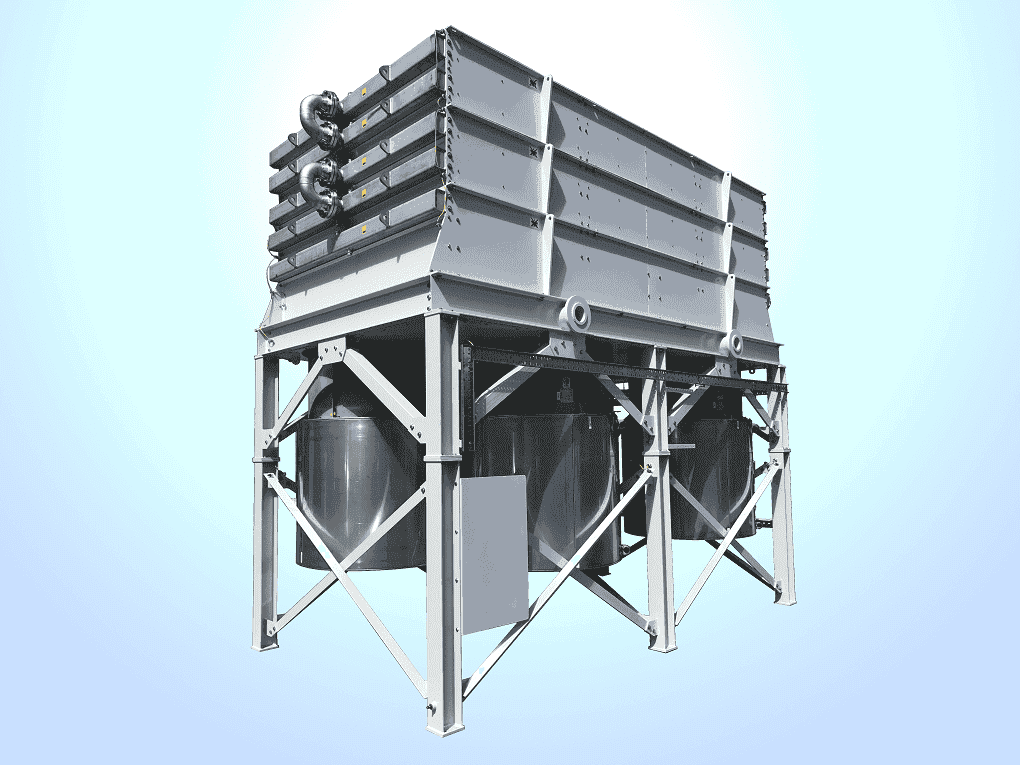

Cooler sizes range significantly from application to application. They generally do not fall into a hazard category as the fluid is a liquid. They are generally a large size and have a high volumetric flow rate to cool. Fouling may be an issue with these heat exchangers, so the design needs to minimise where this is a concern.

These heat exchangers can be subject to client/project specifications which limit the construction methods. Materials are usually carbon steel or stainless steel. Care needs be taken on understanding the chemistry of the water to ensure the materials are selected correctly.