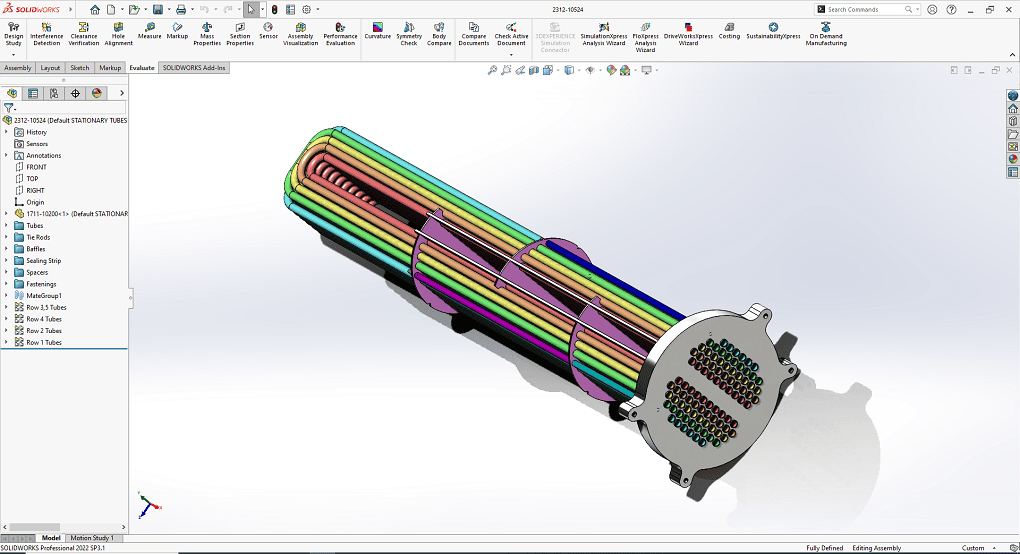

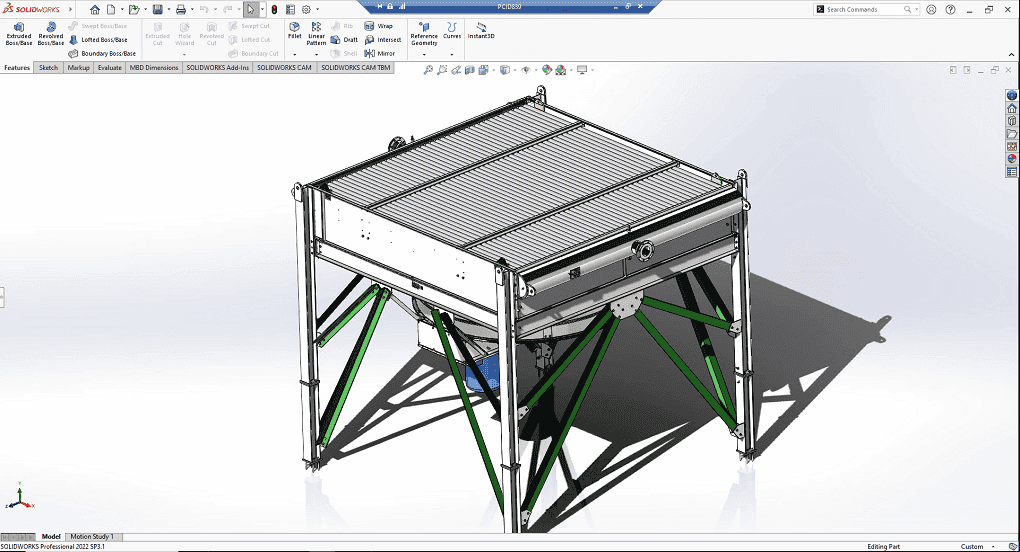

Utilising SolidWorks for 3D modelling for heat exchangers presents a host of benefits. The software's sophisticated tools empower precise design, optimised heat transfer and enhanced efficiency. Engineers can thoroughly analyse and scrutinise designs, identifying potential flaws well ahead of production, resulting in significant time and cost savings. Our experienced drafts people boast years of engineering expertise, ensuring the swift production of accurate and production-ready drawings.

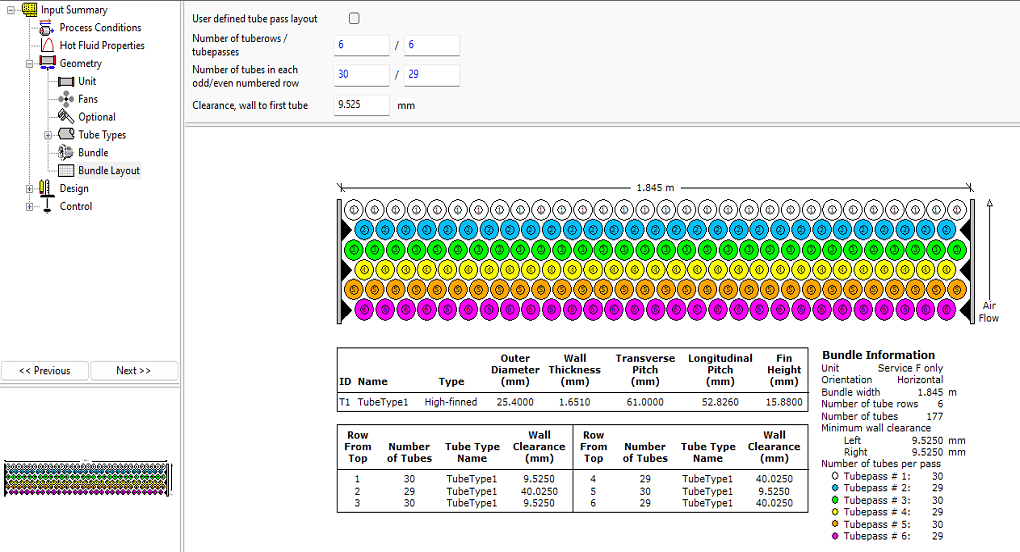

In addition to SolidWorks, we harness the capabilities of HTRI for thermal design. HTRI's specialised tools and features enable us to fine-tune the thermal performance of our heat exchangers, ensuring they meet and exceed industry standards for efficiency and effectiveness. By employing HTRI, we can simulate and optimise heat transfer processes, guaranteeing the utmost efficiency in our designs.

At SHE, our commitment to excellence is reflected in our meticulous approach to data modelling and thermal design. We combine the power of SolidWorks and HTRI to create heat exchangers that stand out for their precision, efficiency, and cost-effectiveness.