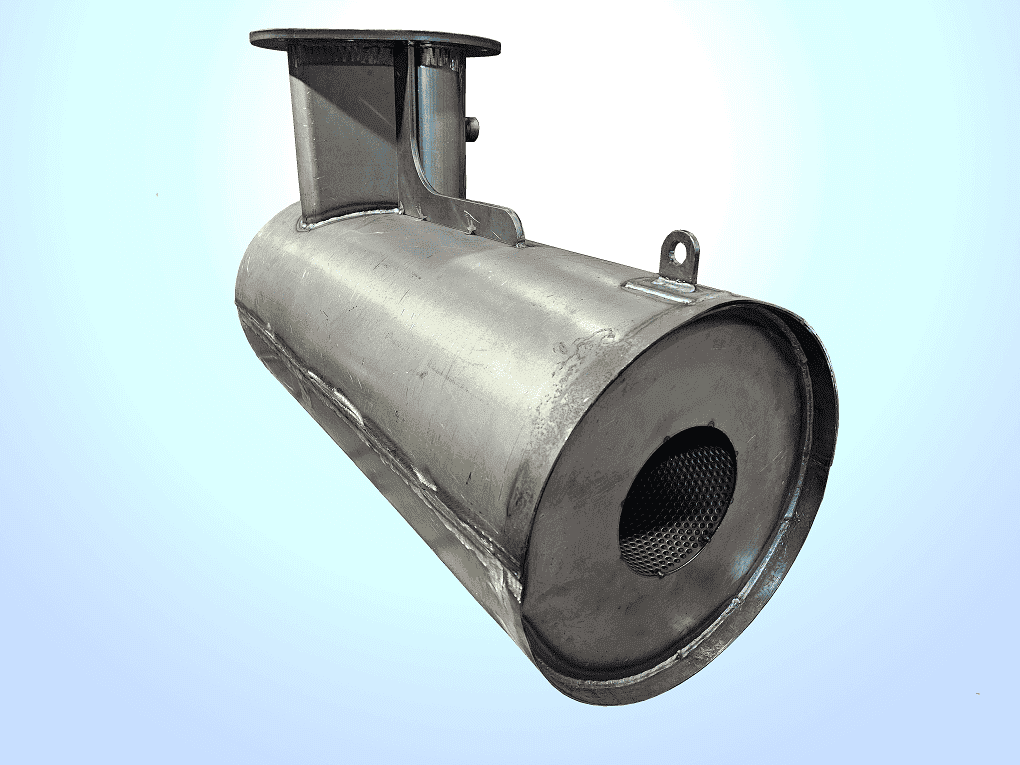

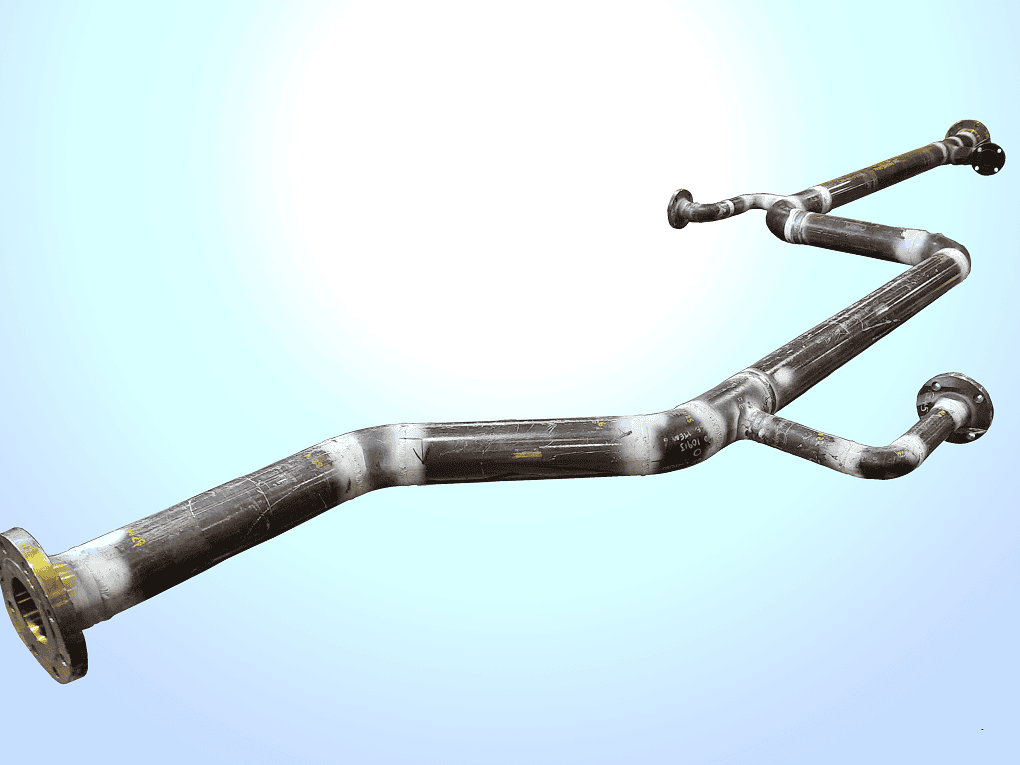

SHE can produce small precision components (<100mm) up to large assemblies (8m x 6m) including pressure vessels with ancillary structural & sheet work. We can cater to your specific needs and specifications, whether you need a single prototype or a large volume of units. We have a flexible and efficient production system, that can adapt to your changing requirements and deadlines.

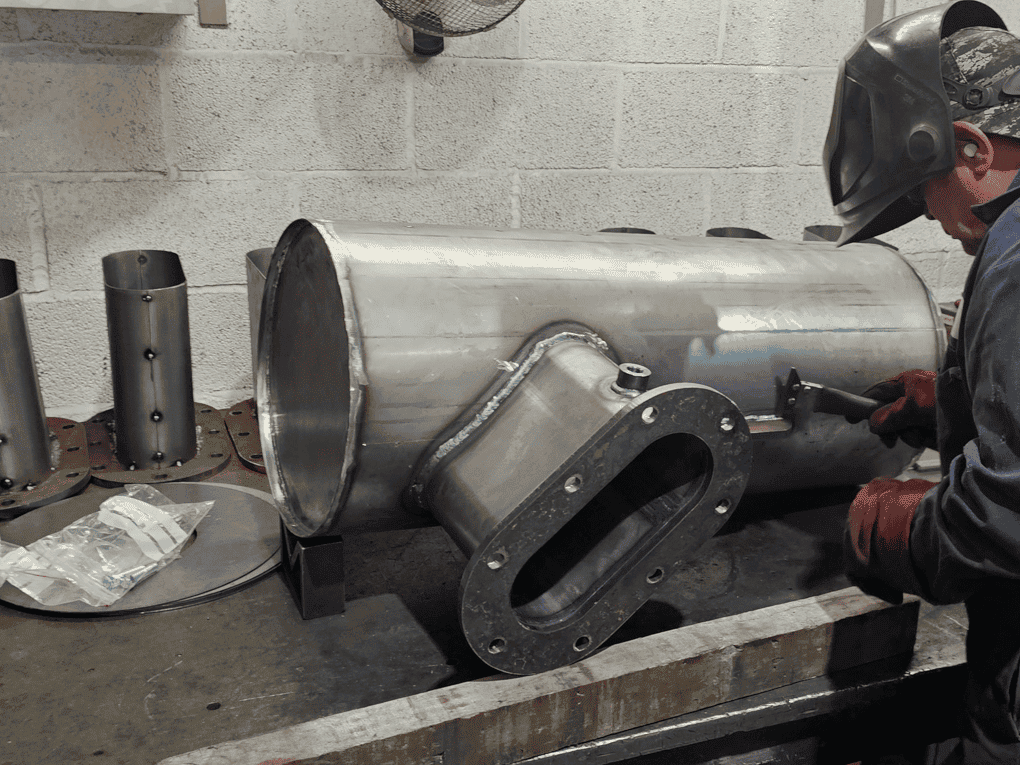

We have a wide variety of tools at our disposal including: a large bed plasma cutter, press brake, machine shop with various 3 axis CNC mills & turning centres, coded & fabrication welding areas, brazing/soldering capability, separate shot blast and paint spray booths and a dedicated assembly area.

Precision components and large assemblies can be produced in various materials including: Carbon Steel (structural & sheet metal), Austenitic & Duplex stainless steel, Cupronickel, Brass & Copper and Aluminium. Highly skilled welders using various welding techniques (TIG, MMA, FCAW & MIG/MAG) and coded (ASME IX or ASME VIII-1) if required.